Every year, over 380 million tons of plastic waste is generated globally—enough to bury Manhattan ankle-deep. Yet within this waste stream lies an untapped $200 billion opportunity, and industrial shredders serve as the master key. This article reveals how modern shredding technology transforms discarded materials into high-value commodities.

Chapter 1: The Alchemy of Size Reduction

Why Shredding = Profit Multiplication

-

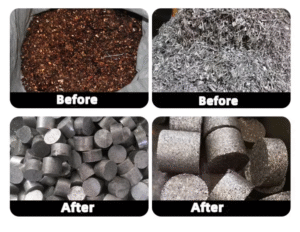

Volume Economics: Pre-shredded materials occupy 1/10th the storage space, slashing logistics costs by up to 60% (World Bank Waste Management Report 2023).

-

Downstream Value: Uniform 8-20mm plastic flakes command 35% higher prices than irregular chunks in recycling markets.

-

Case Study: A Vietnam-based PP woven bag recycler increased annual revenue by $1.2M after upgrading to a 3-stage shredding system.

Chapter 2: The Shredder’s Toolbox for Maximum Yield

Next-Gen Technologies Driving ROI

-

AI-Powered Contaminant Detection

-

Laser scanners identify and eject non-target materials (e.g., metal zippers in textile waste) with 99.7% accuracy.

-

-

Energy Recovery Systems

-

German-engineered “EcoShred” models convert 30% of kinetic heat into supplemental power, reducing net energy consumption.

-

-

Blockchain-Enabled Material Tracing

-

RFID-tagged output allows buyers to verify polymer purity—critical for FDA-grade recycled plastics.

-

Chapter 3: Market-Specific Profit Blueprints

A. E-Waste Gold Rush

-

Apple’s Daisy robot recovers $40M/year in gold/palladium by shredding 200 iPhones/hour.

-

Pro Tip: Use wet shredding to prevent toxic dust during circuit board processing.

B. Tire Pyrolysis Boom

-

Shredded tire chips (2″ size) optimize pyrolysis oil yield by 22% vs whole tires (Rubber Manufacturers Association data).

C. Textile-to-Insulation Conversion

-

Fast-fashion waste processed through cryogenic shredders creates building insulation selling at $12/sq ft.

Chapter 4: The Dark Side – Pitfalls to Avoid

Costly Lessons from the Field

-

The 5-Second Mistake: A Malaysian operator lost $80K in downtime by feeding PET bottles with intact caps (causing 8-hour blade damage).

-

Regulatory Traps: California’s SB-270 mandates shredder noise below 72dB for urban recycling plants—non-compliant units face $15K/day fines.

Chapter 5: Future Frontiers

Emerging Opportunities

-

Space Recycling: NASA-funded projects test microgravity shredders for orbital waste management.

-

Biodegradable Blade Tech: Fungus-treated blades self-sharpen while processing organic waste (MIT prototype shows 400hr+ lifespan).

Conclusion: Your Waste Is Someone Else’s Fortune

As circular economy legislation tightens globally (EU requiring 30% recycled content in packaging by 2030), shredders evolve from simple machines to profit centers. The question isn’t whether to invest—it’s how quickly you can capitalize.