Introduction

The recycling industry operates on razor-thin profit margins, where even minor inefficiencies can turn a profitable operation into a money-losing venture. One of the most critical—yet often overlooked—factors impacting profitability is equipment energy consumption.

For recycling business owners, the choice between hydraulic, electric, and hybrid balers and shredders isn’t just about performance—it’s a direct financial decision. With rising electricity costs, stricter environmental regulations, and fierce competition, optimizing energy efficiency in waste processing equipment has become a make-or-break factor for sustainable operations.

This article explores:

-

Why energy costs are a silent profit killer in recycling

-

Real-world comparisons between hydraulic vs. electric balers and shredders

-

Case studies of businesses that slashed costs by upgrading equipment

-

Future trends in energy-efficient recycling machinery

1. The Hidden Cost of Energy in Recycling

Recycling facilities consume massive amounts of electricity, with balers and shredders accounting for 40-60% of total energy use. Unlike labor or transport costs—which are visible and regularly audited—energy waste often goes unnoticed until it’s too late.

Key Energy Drainers in Recycling Plants

| Equipment | Avg. Power Consumption | Potential Waste |

|---|---|---|

| Hydraulic Baler | 30-50 kW per cycle | 15-25% energy loss in heat/friction |

| Traditional Shredder | 75-150 kW continuous | Blunt blades increase load by 20% |

| Pneumatic Conveyor | 10-20 kW per hour | Leaks cause 30% efficiency drop |

A mid-sized recycling plant processing 50 tons/day can spend $5,000-$10,000 monthly just on electricity. Over five years, this adds up to $300,000-$600,000—enough to buy a new, energy-efficient system outright.

2. Electric vs. Hydraulic: The Energy Showdown

The biggest debate in recycling equipment is: Should you switch from hydraulic to electric?

A) Hydraulic Balers & Shredders

Pros:

✔ High pressure (200+ tons) for dense materials like metal

✔ Proven reliability in heavy-duty industrial settings

Cons:

❌ Energy loss: Only 60-75% efficiency due to heat and fluid friction

❌ Maintenance costs: Hydraulic oil changes, leaks, pump repairs

❌ Noise & heat: Increases cooling costs in facilities

B) Electric Balers & Shredders

Pros:

✔ 85-95% energy efficiency (direct drive = fewer losses)

✔ Lower maintenance: No oil changes, fewer moving parts

✔ Smart features: Variable speed drives optimize power use

Cons:

❌ Limited to <150 tons pressure (not ideal for heavy scrap metal)

❌ Higher upfront cost (but ROI in 2-3 years via energy savings)

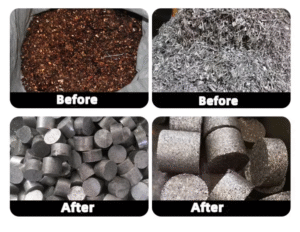

Case Study: A Paper Recycling Plant’s Savings

Before (Hydraulic System)

-

Energy cost: $8,000/month

-

Maintenance: $1,200/month (oil, hoses, pumps)

-

Downtime: 5% due to hydraulic failures

After (Electric Baler Upgrade)

-

Energy cost: $4,500/month (44% reduction)

-

Maintenance: $300/month (75% reduction)

-

Downtime: <1%

Total 5-year savings: $270,000

3. How Smart Shredders Are Cutting Costs Further

The latest innovations are making shredders smarter and more efficient:

A) AI-Powered Load Optimization

-

Sensors detect material density and adjust motor speed

-

Prevents over-shredding (wastes energy) or under-shredding (causes jams)

B) Self-Sharpening Blades

-

Tungsten carbide blades last 3x longer than standard steel

-

Reduces energy waste from dull blades (up to 20% extra load)

C) Energy Recovery Systems

-

Some advanced shredders convert kinetic energy back into electricity

-

Similar to hybrid car regenerative braking

4. Future Trends: Where Energy Savings Are Heading

A) Solar-Powered Recycling Plants

-

Some facilities now run 30-50% on solar during peak hours

-

Battery storage allows off-grid shredding

B) “Pay-Per-Use” Equipment Leasing

-

Startups offer electric balers with kWh-based pricing

-

No upfront cost—just pay for actual energy used

C) Government Incentives

-

Tax credits for switching to electric balers (e.g., U.S. EPA’s ENERGY STAR program)

-

Grants for energy audits in recycling plants

Conclusion: Energy Efficiency = Survival

For recycling businesses, ignoring equipment energy costs is like leaving money on the table. The shift from hydraulic to electric balers and shredders isn’t just an environmental choice—it’s a financial necessity in today’s competitive market.