Introduction

In the global recycling industry, horizontal metal balers have become one of the most widely adopted solutions for processing large volumes of scrap efficiently. Whether in scrap recycling stations, smelting plants, or renewable resource enterprises, the demand for compact, high-density metal bales has surged as businesses seek to optimize storage, reduce transportation costs, and enhance furnace efficiency.

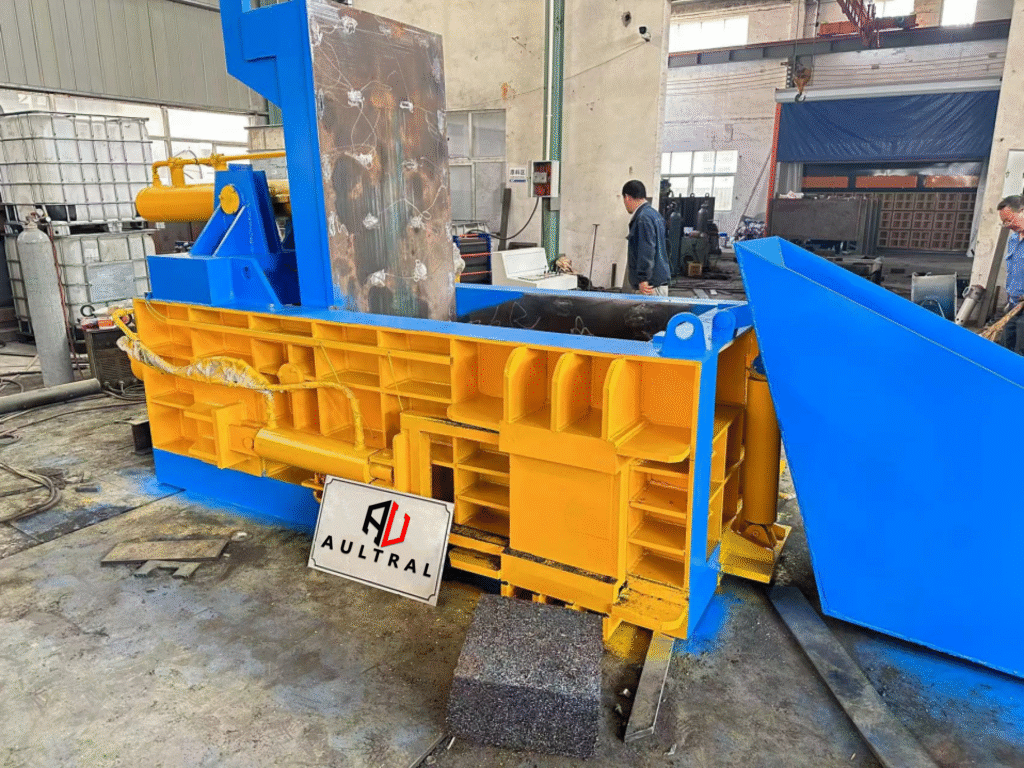

While vertical balers are suitable for smaller-scale operations, enterprises handling high scrap volumes often find them inadequate. This is where the horizontal metal baler comes in: with its high level of automation, continuous feeding design, and large output capacity, it is now considered the mainstream choice for medium-to-large-scale recycling facilities.

This article provides a comprehensive, 3000+ word guide to horizontal metal balers—covering their working principle, advantages, machine configurations, procurement parameters, supplier selection, and future trends. By the end, you will have a clear roadmap to selecting the right baler for your business.

I. Why Horizontal Metal Balers Are Crucial?

1. Addressing the Challenge of Scrap Volume

Loose scrap steel, aluminum, and copper take up excessive yard space and are expensive to transport in uncompressed form. Horizontal balers solve this problem by compressing material into uniform, high-density bales.

2. High Automation for Modern Operations

Unlike vertical balers that often require manual feeding and discharge, horizontal machines support automatic conveyors, hydraulic discharge, and PLC controls. This makes them more suitable for 24/7 industrial-scale operations.

3. Economic Benefits

-

Transportation savings: More material per truckload.

-

Labor savings: Fewer workers needed for feeding/discharging.

-

Higher resale value: Uniform bales fetch better prices in international scrap trade.

4. Environmental Benefits

By reducing energy and fuel consumption during transport and smelting, horizontal balers contribute to sustainability goals and compliance with modern environmental standards.

II. Working Principle of Horizontal Metal Balers

A horizontal metal baler uses hydraulic cylinders to compress scrap within a horizontal chamber. The typical process includes:

-

Feeding: Scrap is loaded into the baler through a conveyor or crane.

-

Compression: Hydraulic cylinders push the material forward into the chamber, compressing it layer by layer.

-

Final Compression: A side cylinder or vertical cylinder applies additional pressure to form dense bales.

-

Discharge: Finished bales are ejected via side push, front ejection, or turnover methods.

This continuous feeding and horizontal compression design allows the machine to handle larger scrap pieces and higher volumes compared to vertical balers.

III. Advantages of Horizontal Metal Balers

-

High Capacity

Designed for enterprises processing tens to hundreds of tons daily. -

Automation

Integration with conveyors and PLC control reduces reliance on manual labor. -

Flexible Bale Sizes

Adjustable bale length and density to fit different transport containers or smelting requirements. -

Versatility

Suitable for steel, aluminum profiles, copper wires, car frames, and mixed scrap. -

Durability

Heavy-duty hydraulic systems and reinforced chambers ensure long service life under demanding conditions. -

Safety

Modern designs include overload protection, automatic alarms, and operator safety guards.

IV. Types of Horizontal Metal Balers

1. Semi-Automatic Horizontal Baler

-

Requires manual tying of bales.

-

Cost-effective for medium-scale operations.

2. Fully Automatic Horizontal Baler

-

Automatic feeding, compression, tying, and discharge.

-

Ideal for large-scale recycling plants and steel mills.

3. Side Push Discharge Baler

-

Hydraulic ram pushes bales sideways out of the chamber.

-

Suitable for continuous operation and large bale sizes.

4. Turnover Discharge Baler

-

Bale is discharged by tilting the chamber.

-

Simple but slower, better for small-to-medium yards.

V. Key Technical Parameters to Consider

When selecting a horizontal baler, focus on the following:

-

Compression Force (Tonnage)

-

Light metals: 80–120 tons

-

Medium scrap: 150–250 tons

-

Heavy steel: 300–600 tons

-

-

Bale Size and Density

Must match your transport method (container vs. truck) and furnace requirements. -

Feeding Method

-

Manual loading (basic model).

-

Conveyor feeding (semi-automatic).

-

Crane/grapple feeding (large automatic systems).

-

-

Discharge Method

Side push, front ejection, or turnover—selected according to site layout. -

Hydraulic System

Quality of pumps, valves, and cylinders determines reliability. -

Control System

Manual, semi-automatic, or PLC full automation. -

Energy Efficiency

Look for machines with optimized hydraulics and energy-saving motors.

VI. Procurement Process and Supplier Evaluation

1. Define Requirements

Clarify scrap type, volume, bale density, site conditions, and budget.

2. Compare Models

Analyze whether you need semi-automatic or fully automatic, and determine discharge type.

3. Assess Suppliers

-

Certifications (ISO, CE).

-

Export experience.

-

Customer references.

4. Inspect Machines

Whenever possible, visit factories or customer sites. Check welding quality, hydraulic components, and chamber design.

5. Review After-Sales Service

Installation, operator training, spare parts supply, and warranty terms.

VII. Common Mistakes in Purchasing

-

Ignoring Long-Term Costs

Cheap machines may lead to high energy bills and frequent breakdowns. -

Over- or Under-Sizing

Buying a machine that is too small reduces efficiency; too large wastes money. -

Neglecting After-Sales Support

Without reliable service, downtime can be extremely costly.

VIII. Case Study: Medium-Scale Scrap Yard

A recycling company processing 80 tons of scrap per day upgraded from a vertical baler to a 200-ton horizontal baler with side push discharge.

Results:

-

Daily output increased by 40%.

-

Labor costs reduced by 30%.

-

Transportation savings of 25% per month.

This case demonstrates how the right horizontal baler directly translates into improved profitability.

IX. Future Trends in Horizontal Metal Balers

-

Intelligent Control Systems

Remote monitoring, fault diagnosis, and IoT integration. -

Energy-Efficient Hydraulics

Variable frequency drives and eco-friendly hydraulic fluids. -

Modular Designs

Machines that can be expanded or reconfigured as capacity grows. -

Safety Enhancements

AI-based monitoring for operator safety and predictive maintenance.

Conclusion

A horizontal metal baler is more than just a machine—it is an investment in efficiency, cost savings, and sustainable growth. Compared with vertical balers, horizontal models offer higher capacity, automation, and adaptability, making them the preferred choice for medium-to-large enterprises in the recycling and smelting sectors.

By following a structured procurement process—define your requirements, compare machine types, evaluate technical specifications, and choose a reliable supplier—you can secure a baler that not only meets your current needs but also supports your business expansion in the future.