Meta Description:

Discover the key differences between fully automatic and semi-automatic horizontal waste paper balers. Learn how each baler type can benefit your recycling operation and which is best for your needs.

♻️ Introduction

When it comes to optimizing paper waste management, choosing the right horizontal waste paper baler is essential. Whether you’re operating a recycling plant, logistics center, or printing factory, a horizontal baler helps compress waste paper into compact bales for easier storage, handling, and transportation.

In this blog, we compare two popular options: Fully Automatic Horizontal Waste Paper Balers and Semi-Automatic Horizontal Waste Paper Balers. We’ll explore their functions, advantages, and how to choose the right one for your business.

🔧 What Does a Horizontal Waste Paper Baler Do?

A horizontal waste paper baler is a machine designed to compress bulky paper waste—like cardboard, newspaper, and office paper—into dense, uniform bales. This not only reduces the space required for storage but also lowers transportation costs and improves recycling efficiency.

Both fully automatic and semi-automatic models operate using hydraulic systems and are widely used in industrial and commercial recycling applications.

⚙️ Fully Automatic Horizontal Waste Paper Baler – Features & Benefits

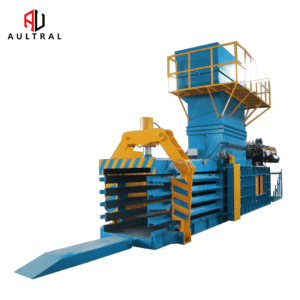

A fully automatic horizontal baler automates the entire process from feeding and compressing to tying and bale ejection. Controlled via a PLC system, it requires minimal human intervention.

Key Benefits:

-

✅ High Productivity: Ideal for high-volume operations running 20+ hours/day

-

✅ Labor Efficiency: Minimal manual labor required

-

✅ Consistent Bale Quality: Uniform bale size and shape

-

✅ Continuous Operation: Automatic feeding and tying reduce downtime

-

✅ Suitable Materials: Cardboard, newspaper, magazines, office paper, packaging materials

Ideal For: Large-scale recycling centers, warehouses, logistics companies, and printing industries.

🛠️ Semi-Automatic Horizontal Waste Paper Baler – Features & Benefits

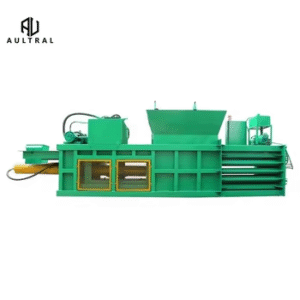

A semi-automatic horizontal baler requires manual involvement during feeding or tying. It provides a more economical solution for businesses that do not need full automation.

Key Benefits:

-

💰 Lower Investment Cost: Budget-friendly option for small to medium enterprises

-

🧑🔧 Simpler Operation: Easier to train staff and maintain

-

🔁 Flexible Baling: Handles various paper types and quantities

-

🔧 Manual Tying: Offers control over bale completion

Ideal For: Medium-sized businesses, small recycling facilities, and companies with lower processing volumes.

📊 Comparison: Fully Automatic vs. Semi-Automatic Horizontal Baler

| Feature | Fully Automatic Baler | Semi-Automatic Baler |

|---|---|---|

| Automation Level | Fully PLC-controlled | Partial (manual feeding or tying) |

| Labor Requirement | Very Low | Moderate |

| Processing Capacity | High | Medium |

| Operation Time | 20+ hours/day | Variable |

| Initial Cost | Higher | Lower |

| Bale Consistency | Excellent | Good |

| Best For | High-volume operations | Small to medium-scale operations |

🔍 SEO Keywords to Remember:

-

horizontal waste paper baler

-

fully automatic paper baler

-

semi-automatic waste baler

-

industrial paper baling machine

-

paper recycling equipment

-

horizontal baler for cardboard

-

waste paper compactor

📝 Final Thoughts

Investing in the right horizontal waste paper baler can significantly impact your operation’s efficiency and bottom line. If you handle large volumes and need speed and automation, a fully automatic baler is the best choice. If you are looking for a more affordable solution with manual flexibility, a semi-automatic baler may be perfect for you.

At Shanghai Aultral Machinery Co., Ltd., we provide both types with customizable options to fit your business needs. Contact us today for a free consultation, machine video, and detailed quotation.

Need help choosing a baler?

📩 Email us today at [Your Email] or visit [Your Website] for expert advice and solutions tailored to your recycling goals.