A Powerful Solution for Waste Management and Recycling Efficiency

In today’s rapidly growing industries, efficient waste management and recycling are more important than ever. Whether you’re running a paper mill, plastic recycling plant, logistics warehouse, or even a large retail chain, dealing with large volumes of recyclable material is a daily challenge. This is where horizontal baler machines come into play.

Horizontal balers are one of the most efficient and time-saving pieces of equipment for compressing recyclable waste into manageable, compact bales. In this article, we will explore everything you need to know about horizontal baler machines, including their benefits, types, working principle, application scenarios, and how to choose the right one for your business.

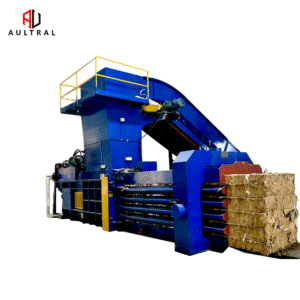

What Is a Horizontal Baler Machine?

A horizontal baler machine is an industrial compactor designed to compress large volumes of recyclable waste—such as cardboard, paper, plastics, textiles, and metal cans—into uniform, dense bales. Unlike vertical balers, which load materials from the top, horizontal balers feed material from the side and offer automatic or semi-automatic operation, making them ideal for high-volume users.

Key Components of a Horizontal Baler

Understanding the structure of a horizontal baler helps in evaluating its performance. The key components include:

-

Feeding Hopper: Where raw material is fed into the machine.

-

Hydraulic System: Provides the power to compress materials using hydraulic cylinders.

-

Main Pressing Chamber: The space where the actual compression takes place.

-

Bale Ejector: Pushes the finished bale out of the chamber.

-

Binding System: For tying the bales using steel wire or plastic straps.

-

PLC Control System (Optional): Used in fully automatic models for programmable control and monitoring.

Types of Horizontal Balers

There are several types of horizontal balers, categorized mainly by their level of automation and the materials they process:

1. Semi-Automatic Horizontal Balers

These require manual strapping and sometimes manual feeding. They are suitable for medium-volume operations and offer a good balance of cost and efficiency.

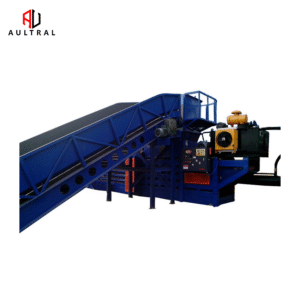

2. Fully Automatic Horizontal Balers

These machines handle everything from feeding to baling to tying automatically. They are ideal for high-volume production environments like recycling centers, paper mills, or logistics hubs.

3. Closed-End Balers

Designed for compressing harder materials like plastics or textiles. The closed end provides stronger compaction.

4. Open-End Channel Balers

Designed for continuous operation, especially for materials like cardboard. These allow the bale to exit from the end while the next compression cycle begins.

Advantages of Using a Horizontal Baler Machine

Here are some key benefits that make horizontal balers a popular choice in modern recycling operations:

✅ 1. High Efficiency

Horizontal balers can process large quantities of material quickly. Fully automatic models can run continuously, significantly reducing labor costs.

✅ 2. Labor Savings

With automation, workers spend less time on handling waste. In many facilities, a single operator can manage the entire baling operation.

✅ 3. Space Optimization

By compressing materials into dense bales, horizontal balers reduce the space required for storing recyclable waste by up to 80%.

✅ 4. Higher Bale Density

Denser bales mean better transportation efficiency and potentially higher revenue when selling to recyclers.

✅ 5. Clean and Organized Work Environment

Proper baling keeps facilities tidy, safe, and more professional-looking, which is important for safety and audits.

Common Materials That Can Be Baled

Horizontal baler machines are versatile and capable of compressing various types of waste, including:

-

Corrugated cardboard (OCC)

-

Mixed office paper

-

Plastic films (LDPE, HDPE)

-

PET bottles

-

Aluminum cans

-

Textile waste

-

Foam or sponge materials

For each material, the bale density and machine requirements may differ. Choosing the right model is crucial for optimal results.

Where Are Horizontal Balers Used?

Horizontal baler machines are widely used across various industries:

| Industry | Application |

|---|---|

| Recycling Centers | High-volume cardboard and plastic waste |

| Printing & Packaging | Paper scraps, trimmings |

| Supermarkets & Warehouses | Corrugated packaging materials |

| Textile Manufacturing | Fabric leftovers, clothing waste |

| Logistics & Distribution | E-commerce packaging waste |

| Agriculture | Baling crop residue, straw, or plastic film |

How to Choose the Right Horizontal Baler for Your Business

Choosing a horizontal baler isn’t just about size or price. Consider the following factors before making a decision:

1. Volume of Waste

Estimate your daily or monthly waste output. Higher output justifies investing in a fully automatic model.

2. Type of Material

Different materials have different compressibility. Plastic films require a different pressure and chamber design than cardboard or metals.

3. Bale Size & Weight Requirements

Do you need small, easy-to-carry bales or large export-grade bales for resale?

4. Available Space

Horizontal balers are larger than vertical ones. Make sure your facility can accommodate the machine and has easy access for forklifts.

5. Budget and ROI

While fully automatic models are more expensive, they offer long-term savings in labor and time. Semi-automatic models are more affordable for startups or small businesses.

6. Power Supply

Check the power requirements (usually 380V, 3-phase for industrial models). Some custom models can be designed for 220V or alternative power sources.

Case Study: Horizontal Baler in Action

Client: A logistics company in São Paulo, Brazil

Challenge: Daily accumulation of over 1 ton of cardboard and plastic waste

Solution: Installed a fully automatic horizontal baler with conveyor feeding

Results:

-

Reduced waste handling time by 70%

-

Saved two workers per shift

-

Sold compressed bales to local recycling companies, creating a new revenue stream

Maintenance Tips for Long-Term Use

To keep your baler working efficiently, follow these tips:

-

Daily cleaning of the feeding area and hydraulic system

-

Weekly checks of hydraulic fluid levels

-

Monthly inspections for wear and tear on cylinders and blades

-

Replace wires/straps regularly to avoid jamming

-

Follow the manufacturer’s manual for scheduled servicing

Conclusion

A horizontal baler machine is not just an equipment investment — it’s a game-changer for operational efficiency, environmental compliance, and even profitability. Whether you’re a factory, warehouse, or recycling company, this powerful tool helps you take control of waste management and turn it into value.

If you’re ready to explore options, compare models, or request a free consultation, feel free to contact us today. Our team is ready to help you choose the perfect baler for your needs.

🔧 Need a Custom Baler Solution?

We offer OEM/ODM services, on-site installation guidance, and after-sales support in over 50 countries.

📩 Get in touch now for a quote or catalog!