1. Working Principle Comparison

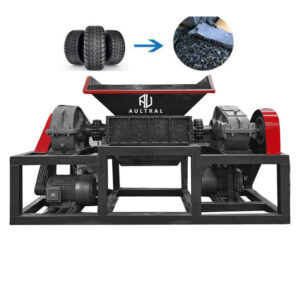

Dual-Shaft Shredder

-

Design: Two counter-rotating shafts with interlocking blades create a shearing and tearing action.

-

Power: Hydraulic or high-torque electric drive (55–400 kW).

-

Blades: Replaceable “hook” or “square” blades with customizable tooth profiles.

-

Best for: High-volume processing of tough, bulky, or elastic materials.

Single-Shaft Shredder

-

Design: A single rotating shaft with fixed or replaceable blades uses a ripping and cutting motion.

-

Power: Electric motor (15–110 kW), lower energy consumption.

-

Blades: Helical or hook-shaped blades (often one-piece).

-

Best for: Smaller-scale processing of soft or thin materials.

Table: Key Differences Between Dual-Shaft and Single-Shaft Shredders

| Feature | Dual-Shaft Shredder | Single-Shaft Shredder |

|---|---|---|

| Crushing Force | High shearing force | Moderate tearing force |

| Material Size | Handles large, irregular scrap | Better for pre-cut or small waste |

| Maintenance | Replaceable blade segments | Full blade replacement |

| Noise Level | 80–90 dB (with enclosures) | 70–85 dB |

2. Material-Specific Recommendations

Dual-Shaft Shredder Ideal For:

✅ Hard Metals (e.g., engine blocks, scrap steel) – High torque prevents stalling.

✅ Elastic Materials (e.g., tires, rubber, cables) – Anti-wrapping design.

✅ Bulky Waste (e.g., appliances, demolition debris) – Wide hopper (up to 1500mm).

Single-Shaft Shredder Ideal For:

✅ Soft Plastics (e.g., PET bottles, films) – Gentle shredding prevents melting.

✅ Fibrous Waste (e.g., textiles, paper) – Efficient tearing without clogging.

✅ Thin Metals (e.g., aluminum cans, sheet metal) – Lower energy consumption.

Pro Tip: Test your material’s hardness (Mohs scale), density (kg/m³), and tensile strength before deciding.

3. Key Decision Factors

1. Throughput Requirements

-

Dual-Shaft: Best for >10 tons/hour continuous operation.

-

Single-Shaft: Suitable for <5 tons/hour batch processing.

2. Maintenance & Operating Costs

-

Dual-Shaft:

-

Blade life: 800–1,200 hours (individual teeth replaceable).

-

Higher upfront cost but lower cost per ton in high-volume applications.

-

-

Single-Shaft:

-

Blade life: 1,500+ hours (but requires full blade replacement).

-

Cheaper upfront, ideal for small-scale recyclers.

-

3. Safety & Automation

-

Dual-Shaft:

-

Auto-reverse function prevents jams.

-

IoT-enabled models offer real-time monitoring.

-

-

Single-Shaft:

-

Mechanical emergency stop (slower response).

-

Simpler operation for low-risk materials.

-

4. Real-World Case Studies

Case 1: Scrap Metal Processor

-

Problem: Single-shaft shredder struggled with car engines (frequent jams).

-

Solution: Upgraded to dual-shaft shredder with hydraulic pusher.

-

Result:

-

70% fewer breakdowns.

-

Output increased from 3 t/h to 7 t/h.

-

Case 2: Plastic Recycling Plant

-

Problem: Dual-shaft shredder over-processed PP granules.

-

Solution: Switched to single-shaft granulator (adjusted screen size).

-

Result:

-

Energy savings: 40%.

-

Material consistency: >98% uniform granules.

-

5. Interactive Tools for Buyers

-

Shredder Selector Tool: Upload material photos → Get machine recommendations.

-

TCO Calculator: Compare 5-year costs (purchase + maintenance + energy).

6. Common Myths Debunked

❌ “More power = better performance” → Oversized shredders waste energy.

❌ “Dual-shaft is always more expensive” → Long-term ROI may be better.

Conclusion: How to Choose

-

For heavy-duty scrap: Dual-shaft shredders deliver higher efficiency.

-

For light, uniform waste: Single-shaft shredders save costs.