In today’s logistics, retail, and manufacturing industries, cardboard waste is generated in large volumes every day. Without proper handling, loose cardboard boxes take up valuable space, increase transportation costs, and create safety and hygiene issues. A cardboard baler is the most efficient and cost-effective solution to compress waste cardboard into compact, manageable bales, helping businesses improve recycling efficiency and reduce operating costs.

What Is a Cardboard Baler?

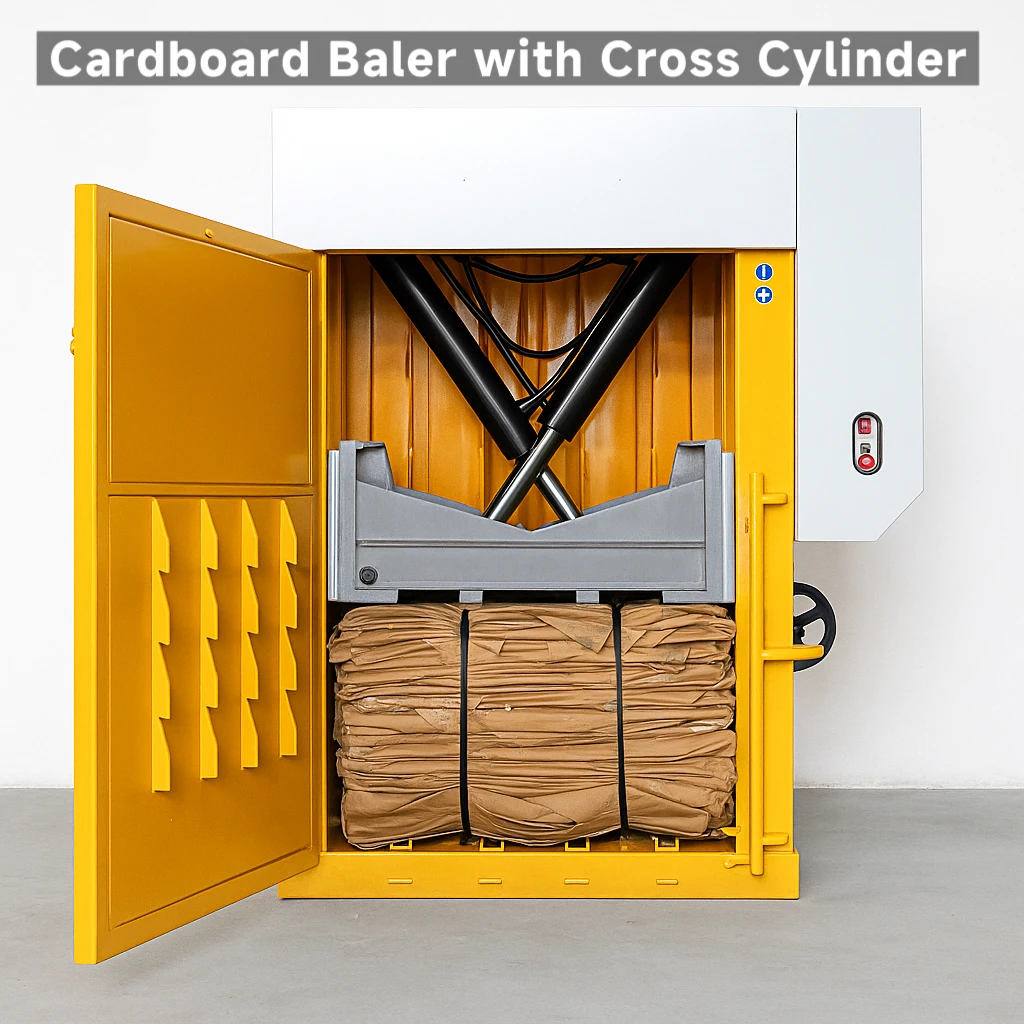

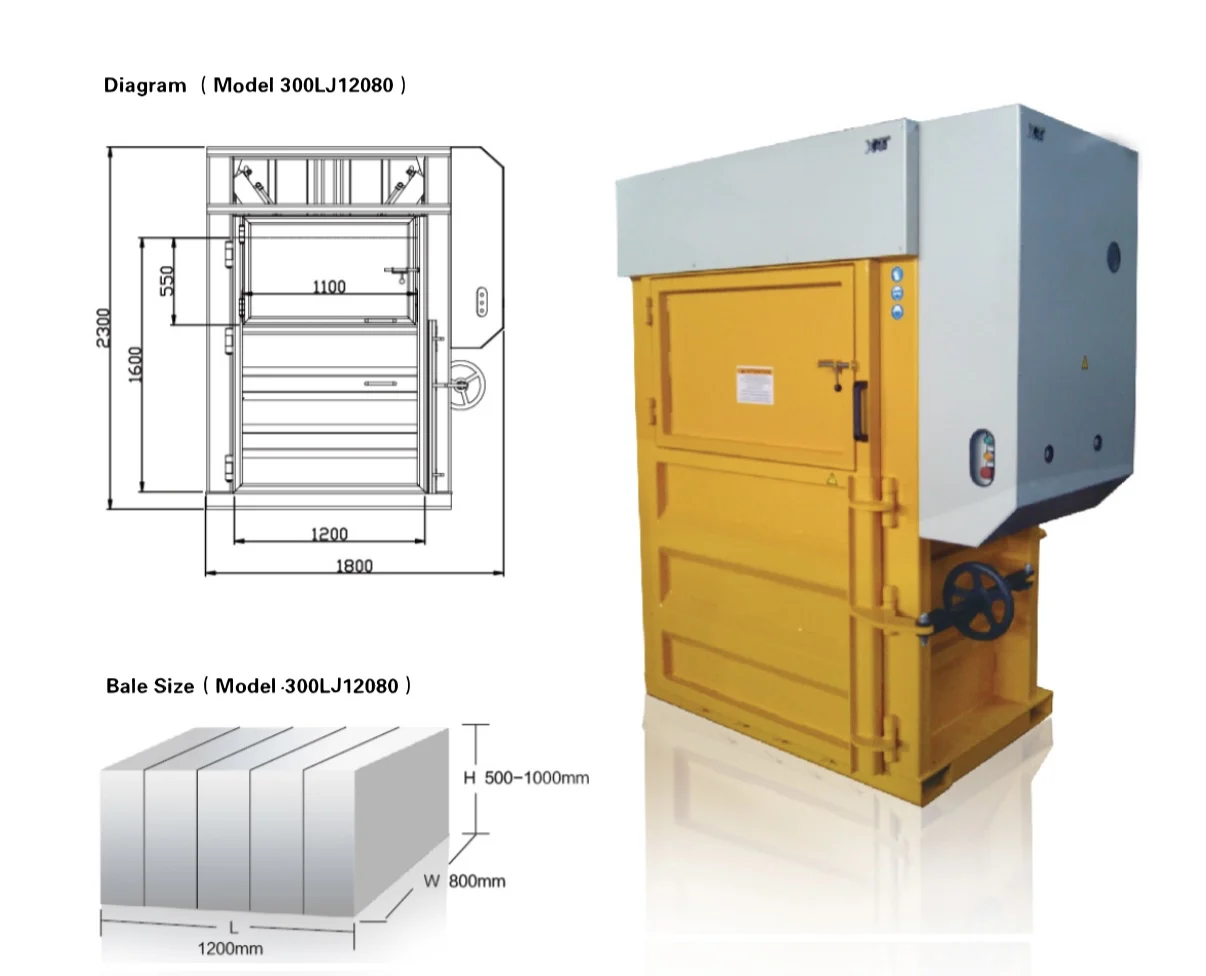

A cardboard baler is a hydraulic recycling machine designed to compress waste cardboard, cartons, and paperboard into dense bales. These bales are easy to store, transport, and sell to recycling companies. Cardboard balers are widely used in warehouses, supermarkets, factories, distribution centers, printing plants, and recycling stations.

By applying strong hydraulic pressure, a cardboard baler significantly reduces the volume of cardboard waste—often by up to 80–90%—making waste management cleaner, safer, and more efficient.

Types of Cardboard Balers

There are several types of cardboard balers available on the market, each suitable for different production scales and operational needs.

Vertical Cardboard Baler

A vertical cardboard baler is compact and space-saving, making it ideal for small to medium businesses. Cardboard is loaded manually from the front, and bales are typically tied with wire or plastic straps. Vertical balers are easy to operate, energy-efficient, and cost-effective.

Best for:

Retail stores, supermarkets, small warehouses, and offices.

Horizontal Cardboard Baler

A horizontal cardboard baler is designed for high-volume cardboard recycling. It can be semi-automatic or fully automatic, often equipped with conveyor feeding systems. Horizontal balers produce uniform, high-density bales suitable for large-scale recycling operations.

Best for:

Large warehouses, logistics centers, paper mills, and recycling plants.

Automatic Cardboard Baler

An automatic cardboard baler features PLC control, automatic feeding, automatic tying, and continuous operation. It greatly reduces labor costs and increases processing efficiency, making it the preferred choice for industrial applications.

Key Benefits of Using a Cardboard Baler

Investing in a cardboard baler offers multiple operational and environmental advantages.

Reduced Waste Volume

By compressing loose cardboard into dense bales, a cardboard baler dramatically reduces storage space requirements and keeps working areas clean and organized.

Lower Transportation Costs

Compressed cardboard bales are easier and cheaper to transport compared to loose cartons, helping businesses save significantly on logistics expenses.

Improved Recycling Value

Well-compressed, uniform cardboard bales are more attractive to recycling companies and often achieve better resale prices.

Enhanced Workplace Safety

Loose cardboard can cause clutter and fire hazards. A cardboard baler minimizes these risks by keeping waste properly contained.

Environmental Sustainability

Using a cardboard baler supports sustainable waste management practices by promoting recycling and reducing landfill use.

How to Choose the Right Cardboard Baler

Selecting the right cardboard baler depends on several key factors:

-

Daily Cardboard Volume

Determine how much cardboard waste you generate per day or per shift. Higher volumes require horizontal or automatic balers. -

Bale Size and Weight Requirements

Some recycling companies have specific requirements for bale dimensions and weight. -

Available Space

Vertical balers are suitable for limited space, while horizontal balers require more installation area. -

Automation Level

Manual, semi-automatic, or fully automatic operation should be chosen based on labor availability and efficiency goals. -

Power Supply

Ensure the cardboard baler matches your local voltage and electrical standards.

Applications of Cardboard Balers

Cardboard balers are widely used across various industries, including:

-

Logistics and distribution centers

-

E-commerce warehouses

-

Supermarkets and retail chains

-

Manufacturing plants

-

Printing and packaging factories

-

Recycling and waste management companies

In all these applications, a cardboard baler helps streamline waste handling and improve operational efficiency.

Maintenance and Safety Considerations

Modern cardboard balers are designed for durability and long service life, but regular maintenance is essential. Routine checks on hydraulic oil, cylinders, seals, and electrical components help ensure stable performance. Operators should receive proper training and follow safety guidelines, including emergency stop procedures and load limits.

Why a Cardboard Baler Is a Smart Investment

A cardboard baler is not just a waste-handling machine—it is a long-term investment that delivers measurable returns. By reducing labor costs, saving space, lowering transportation expenses, and improving recycling income, a cardboard baler quickly pays for itself while supporting environmentally responsible operations.

As cardboard waste continues to increase globally, the demand for efficient recycling solutions is higher than ever. A cardboard baler provides a practical, reliable, and sustainable way to manage cardboard waste across industries of all sizes. Whether you choose a vertical, horizontal, or automatic model, investing in the right cardboard baler will help your business operate more efficiently, reduce costs, and contribute to a greener future.