Bite, Tear, Crush: The Science Behind Power

When you hear the word “shredder,” the first image that comes to mind may be a paper shredder in an office. But industrial shredders are a completely different beast. They are powerful, heavy-duty machines designed to bite, tear, and crush a wide range of materials—from plastics and paper to wood, rubber, textiles, and even entire cars. These machines are the unsung heroes of recycling, waste management, and resource recovery. In this blog, we will dive deep into the science behind shredding power, how it works, and why it matters in today’s world.

The Core Principle of an Industrial Shredder: Mechanical Reduction

At its heart, shredding is about mechanical size reduction. By cutting or tearing materials into smaller, more manageable pieces, shredders make waste easier to transport, store, and recycle. The science behind this involves the interaction of blades, torque, speed, and force. Each factor contributes to the way a shredder “bites” into materials and transforms them from bulk waste into uniform shreds.

Unlike crushers, which primarily compress and break materials through impact, shredders focus on shearing and tearing. The geometry of the blades and the way they rotate determine how effective the shredding process will be.

Anatomy of a Shredder: Blades, Motors, and Torque

1. The Blades

The blades are the heart of the shredder. Typically made of hardened steel, they are designed to withstand enormous pressure and continuous wear. The design can vary depending on the application:

- Hooked Blades: Ideal for grabbing and tearing fibrous materials like textiles or rubber.

- Flat Blades: Better suited for plastic shredder machines where slicing is needed.

- Custom Tooth Designs: Created for specialized applications, such as shredding wood or e-waste.

2. The Motor

The motor provides the raw power. Industrial shredders can be powered by electric motors or hydraulic systems. Electric motors are common for medium-duty shredders, while hydraulics are used for high-torque, heavy-duty machines that need to handle dense or bulky materials.

3. Torque and Speed

Torque is the twisting force that allows a shredder to bite into tough materials. High torque, combined with low speed, gives shredders the ability to handle materials like metal sheets or car bodies. On the other hand, high-speed, lower-torque shredders are better for light materials like paper and plastics.

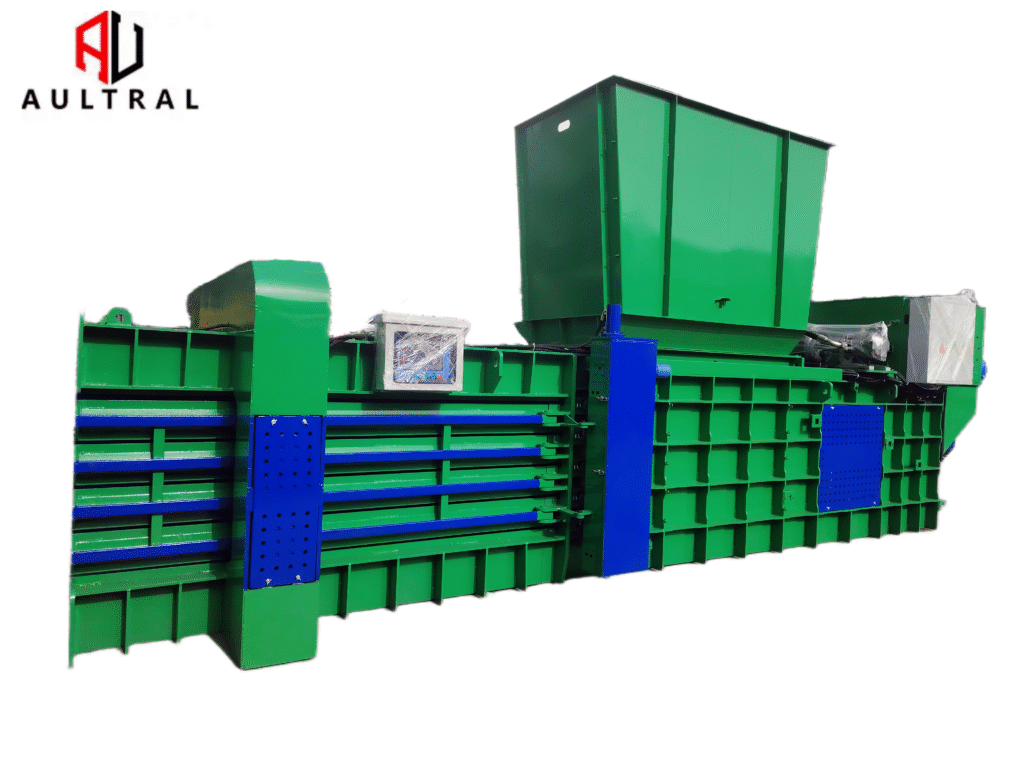

Types of Industrial Shredders

Not all shredders are created equal. Depending on the material and the desired output, different designs are used:

- Single-Shaft Shredders: Equipped with one rotating shaft and a hydraulic pusher to press materials into the blades. Best for plastics and light metals.

- Double-Shaft Shredders: Two counter-rotating shafts tear materials apart. Excellent for bulky waste like tires, wood, and municipal waste.

- Four-Shaft Shredders: These add two more shafts for greater precision and smaller output sizes. Common in applications requiring high uniformity.

- Hammer Mills: Technically more crushers than shredders, but they use hammers mounted on a rotating shaft to pulverize materials.

The Science of Shearing and Tearing in Shredding

The key to shredding lies in shearing—the process of applying opposing forces to cut through materials. Imagine using scissors: the blades don’t press directly down; they pass by each other at an angle. Industrial shredders work the same way, except with much greater force and precision.

When blades are properly aligned, the shredder achieves a clean, efficient cut. Misalignment or dull blades lead to energy waste, overheating, and uneven output. That’s why blade maintenance is a crucial part of the shredding science.

Energy Efficiency and Material Flow in Waste Recycling

Behind every shredder is an energy equation. How much power is consumed per kilogram of shredded material? Efficiency depends on both the machine design and the type of material. For example, shredding lightweight plastic film requires less torque but more speed to avoid clogging. Meanwhile, shredding aluminum cans or copper cables needs slow, high-torque force.

Material flow is equally important. A well-designed shredder ensures continuous feeding and discharge, preventing jams. That’s why many machines are equipped with conveyors, pushers, and smart sensors to regulate input.

Shredding Applications Across Industries

Shredders are not just about reducing waste. They add value across industries by transforming bulky or unusable materials into resources.

- Plastics Recycling: A plastic shredder breaks down bottles, containers, and films into flakes ready for washing and reprocessing.

- Paper and Cardboard: Large-volume shredders prepare waste paper for pulping in paper mills.

- Metal Recycling: Shredders handle aluminum, copper, and steel scrap, making them suitable for smelting and reuse.

- Wood and Biomass: Shredded wood can be turned into pellets or compost.

- E-Waste Recycling: From old computers to smartphones, shredders safely dismantle and prepare components for material recovery.

- Automotive Recycling: Entire vehicles can be fed into massive shredders, separating valuable metals from plastics and glass.

Safety and Environmental Impact of Shredders

Industrial shredders are powerful, but with great power comes responsibility. Safety mechanisms such as emergency stop systems, overload sensors, and protective guards are built in to protect operators.

From an environmental perspective, shredders play a vital role in promoting the circular economy. By enabling efficient recycling, they reduce landfill waste, conserve natural resources, and lower carbon footprints.

The Future of Shredding Technology

Shredding technology continues to evolve with advances in automation, AI, and material science.

- Smart Shredders: Equipped with sensors and AI to automatically adjust torque and speed based on material type.

- Durable Materials: New alloys and coatings extend blade life and reduce downtime.

- Integration with Sorting Systems: Shredders working hand-in-hand with magnetic separators, air classifiers, and optical sorters to maximize material recovery.

The future will likely see shredders becoming more energy-efficient, adaptive, and central to global recycling networks.

Conclusion: Why Shredding Power Matters

The science behind shredding is more than brute force. It’s an intricate balance of engineering, physics, and material science. From the design of the blades to the torque of the motor, every detail matters in determining how effectively a shredder can bite, tear, and crush.

Industrial shredders may not always be visible in our daily lives, but they are at the heart of waste recycling and resource recovery. The next time you see a recycled product, remember that somewhere along the line, a shredder played a critical role in transforming waste into something valuable.

Extra Insight:

For businesses considering an investment in shredding equipment, the key takeaway is that one size does not fit all. Choosing the right shredder involves analyzing the type of material, desired output size, and required throughput. For example, a recycling plant focused on PET bottles may prioritize high-speed shredders with precise blade designs, while a scrapyard handling cars needs massive, slow-speed, high-torque machines. Furthermore, maintenance strategies—such as regular blade sharpening, lubrication, and system checks—can extend machine life and optimize performance. By understanding the science behind shredding, businesses can maximize efficiency, reduce operational costs, and contribute to a greener planet. Investing in shredders is not just about waste reduction; it’s about unlocking value from materials that would otherwise end up in landfills. This makes shredders not only machines of destruction but also engines of sustainability.