Introduction: The Growing Demand For Efficient Metal Recycling

As global metal recycling continues to expand, recycling plants, scrap yards, and metal processing facilities are under increasing pressure to handle larger volumes of scrap more efficiently. Loose metal waste not only occupies excessive space but also increases transportation costs and creates safety risks.

This is where the Horizontal Metal Baler becomes a critical piece of equipment. Designed for high output, heavy-duty performance, and continuous operation, horizontal metal balers are widely used in modern metal recycling lines.

In this article, we will explain what a horizontal metal baler is, why it is essential, how it works, and most importantly, how to choose the right model for your business.

What Is A Horizontal Metal Baler?

A Horizontal Metal Baler is an industrial hydraulic machine used to compress loose metal scrap into dense, rectangular bales. Unlike vertical balers, horizontal balers compress material in a horizontal direction, allowing for larger feed openings, higher throughput, and automated operation.

Common Materials Processed By Horizontal Metal Balers

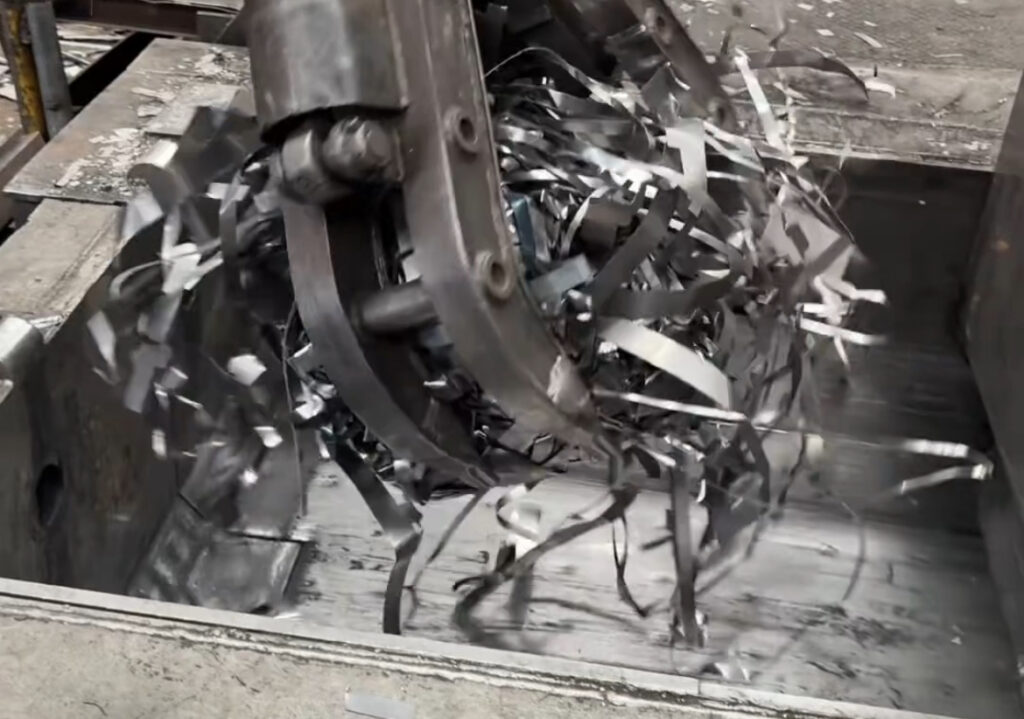

Horizontal metal balers are suitable for a wide range of metal materials, including:

-

Aluminum scrap

-

Steel scrap

-

Copper wire

-

Iron shavings and turnings

-

Sheet metal offcuts

-

Cans and light metal profiles

Because of their strong hydraulic pressure and rigid structure, these machines can handle both light and medium-density metal materials efficiently.

Why Choose A Horizontal Metal Baler?

Investing in a horizontal metal baler is not just about buying a machine—it is about improving efficiency, reducing costs, and optimizing your recycling workflow.

High Compression And Stable Bale Density

Horizontal metal balers apply strong and consistent hydraulic force, producing bales with uniform size and high density. This makes storage, stacking, and transportation significantly easier.

Continuous And Automated Operation

Most horizontal metal balers are designed for semi-automatic or fully automatic operation. With features such as automatic feeding conveyors and PLC control systems, operators can run the machine continuously with minimal manual intervention.

Lower Transportation Costs

Dense metal bales reduce the number of truckloads required, cutting logistics costs dramatically. This advantage becomes especially important when shipping scrap over long distances or exporting metal waste.

Improved Workplace Safety

Loose scrap metal can be hazardous. By compressing metal into neat bales, horizontal balers help maintain a cleaner and safer working environment.

Ideal For Large-Scale Recycling Facilities

If your operation processes large volumes of metal daily, a horizontal metal baler offers far higher efficiency than manual or vertical baling solutions.

How Does A Horizontal Metal Baler Work?

Understanding the working process helps you use the machine correctly and choose the right configuration.

Step 1: Feeding The Material

Metal scrap is loaded into the feeding chamber. This can be done manually, by forklift, or through an automatic conveyor system depending on the production line setup.

Step 2: Horizontal Compression

A powerful hydraulic cylinder pushes the compression ram horizontally, pressing the metal scrap into the compression chamber. The pressure removes air gaps and compacts the material tightly.

Step 3: Bale Forming And Tying

Once the desired bale size and density are reached, the bale is tied using steel wires or straps. Most horizontal metal balers support multiple tying lines to ensure bale stability.

Step 4: Bale Discharge

The finished bale is automatically pushed out of the chamber, ready for storage or transportation.

Key Components Of A Horizontal Metal Baler

To evaluate machine quality, it is important to understand its main components.

Hydraulic System

The hydraulic system provides the compression force. High-quality pumps, valves, and oil tanks ensure stable pressure and long service life.

Main Compression Cylinder

This is the core of the baler. Larger cylinder diameter usually means stronger compression force and higher bale density.

Feeding Chamber

A wide and long feeding opening allows faster material loading and improves overall productivity.

PLC Control System

Modern horizontal metal balers are equipped with PLC systems for easy operation, fault diagnosis, and automatic cycling.

Bale Tying System

Steel wire tying systems ensure the bale remains compact during handling and transport.

Horizontal Metal Baler Vs Vertical Metal Baler

Many customers ask whether they should choose a horizontal or vertical metal baler.

Horizontal Metal Baler Advantages

-

Higher output capacity

-

Continuous operation

-

Larger feed opening

-

Suitable for automation

-

Better for large recycling plants

Vertical Metal Baler Advantages

-

Smaller footprint

-

Lower initial investment

-

Suitable for small workshops

If you process large volumes of metal scrap daily, a horizontal metal baler is clearly the better choice.

How To Choose The Right Horizontal Metal Baler Model

Selecting the right model is critical to achieving the best return on investment.

Determine Your Material Type

Different metals have different densities. Aluminum cans require less pressure, while steel scrap needs stronger compression. Always choose a model designed for your primary material.

Evaluate Daily Processing Capacity

Calculate how many tons of metal you need to process per day. This determines the required motor power, hydraulic force, and automation level.

Consider Bale Size And Weight

Standard bale sizes make transportation and resale easier. Confirm the bale dimensions required by your downstream buyers or logistics partners.

Check Compression Force

Compression force is usually measured in tons. Common models range from 60 tons to over 200 tons. Higher force means denser bales but also higher power consumption.

Power Supply And Voltage

Make sure the machine matches your local power supply, including voltage, phase, and frequency (50Hz or 60Hz).

Automation Level

Fully automatic horizontal metal balers reduce labor costs but require a higher initial investment. Semi-automatic models may be suitable for medium-sized facilities.

Installation And Operation Tips

Proper installation and operation ensure long-term performance.

Site Preparation

Ensure the foundation is strong enough to support the machine weight and vibration. Adequate space is required for feeding, bale discharge, and maintenance.

Operator Training

Even automated machines require trained operators. Proper training reduces breakdowns and improves safety.

Routine Maintenance

Regular oil checks, seal inspections, and hydraulic system maintenance significantly extend machine life.

Common Applications Of Horizontal Metal Balers

Horizontal metal balers are widely used in:

-

Scrap metal recycling plants

-

Automobile dismantling facilities

-

Manufacturing factories

-

Metal processing workshops

-

Waste management centers

Their flexibility makes them suitable for both standalone operation and integrated recycling lines.

Future Trends In Horizontal Metal Baler Technology

With increasing environmental regulations and labor costs, horizontal metal balers are evolving toward:

-

Higher automation

-

Energy-efficient hydraulic systems

-

Smart PLC monitoring

-

Integration with shredders and conveyors

These trends help recycling businesses stay competitive and sustainable.

Conclusion: Is A Horizontal Metal Baler Worth The Investment?

For businesses handling large volumes of metal scrap, a Horizontal Metal Baler is not just a machine—it is a productivity multiplier. By reducing volume, lowering transportation costs, improving safety, and supporting automated workflows, it delivers strong long-term value.

Choosing the right model based on material type, capacity, and automation level ensures maximum efficiency and return on investment. With the right horizontal metal baler, your recycling operation can move to the next level.