♻️ Metal Balers: The Secret Weapon for Turning Scrap into Gold

In today’s manufacturing and recycling industries, scrap metal recycling is no longer just about protecting the environment—it’s also a major profit driver. And at the heart of this transformation is one powerful machine: the Metal Baler.

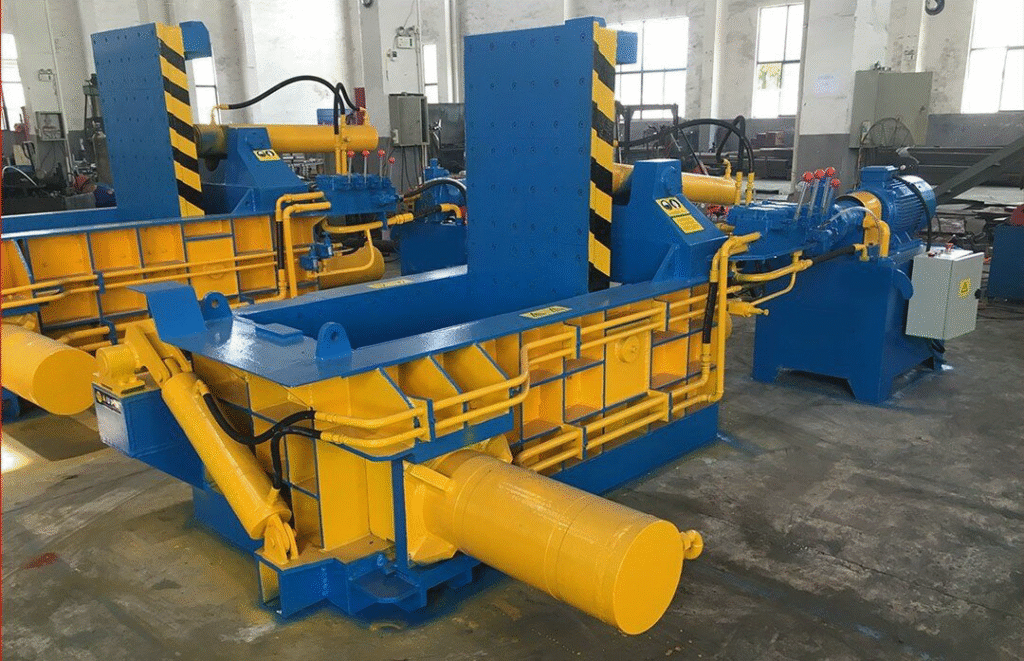

1️⃣ What is a Metal Baler?

A metal baler is a machine that compresses loose scrap metal into dense, uniform bales using high hydraulic pressure. It can handle:

-

Scrap Steel

-

Aluminum

-

Copper

-

Stainless Steel

-

Various metal offcuts and waste

Once baled, metal becomes easier to store and transport and can be smelted more efficiently during recycling.

2️⃣ Why Every Business Needs One

💡 Save on Transportation Costs – Baled metal takes up 50%–80% less space, allowing you to transport more per load.

💡 Increase Recycling Value – Denser, more uniform bales often fetch better prices in the scrap market.

💡 Eco-Friendly – Reduces storage space, prevents material loss, and minimizes environmental pollution.

💡 Boost Company Image – Businesses with modern baling equipment are seen as efficient, green, and forward-thinking.

3️⃣ Key Advantages of a Metal Baler

| Advantage | Description |

|---|---|

| High-Pressure Hydraulic System | Ensures tight, compact bales. |

| Automated Operation | Cuts labor costs and improves workplace safety. |

| Multiple Loading Methods | Top-loading, side-loading, or front-loading to suit different material shapes. |

| Customizable | Tailored bale sizes and chamber dimensions for specific needs. |

4️⃣ Industries that Benefit from Metal Balers

Metal balers are essential in:

-

Scrap Metal Recycling Plants

-

Steel Mills

-

Aluminum Processing Plants

-

Shipbuilding and Dismantling Yards

-

Automotive Recycling Centers

- Hardware and Machinery Factories

5️⃣ The Future: Smarter and Greener

With the rise of Industry 4.0, the next generation of metal balers is moving towards smart control systems, energy-efficient hydraulics, and remote monitoring. In the future, they won’t just be machines—they’ll be data-driven, intelligent recycling partners.