What Is A Small Shredder

A small shredder is a compact machine designed to break down different materials into smaller, more manageable pieces. Unlike large industrial shredders that demand significant space and investment, a small shredder is built for workshops, recycling centers, offices, farms, and even households where space and budget are limited.

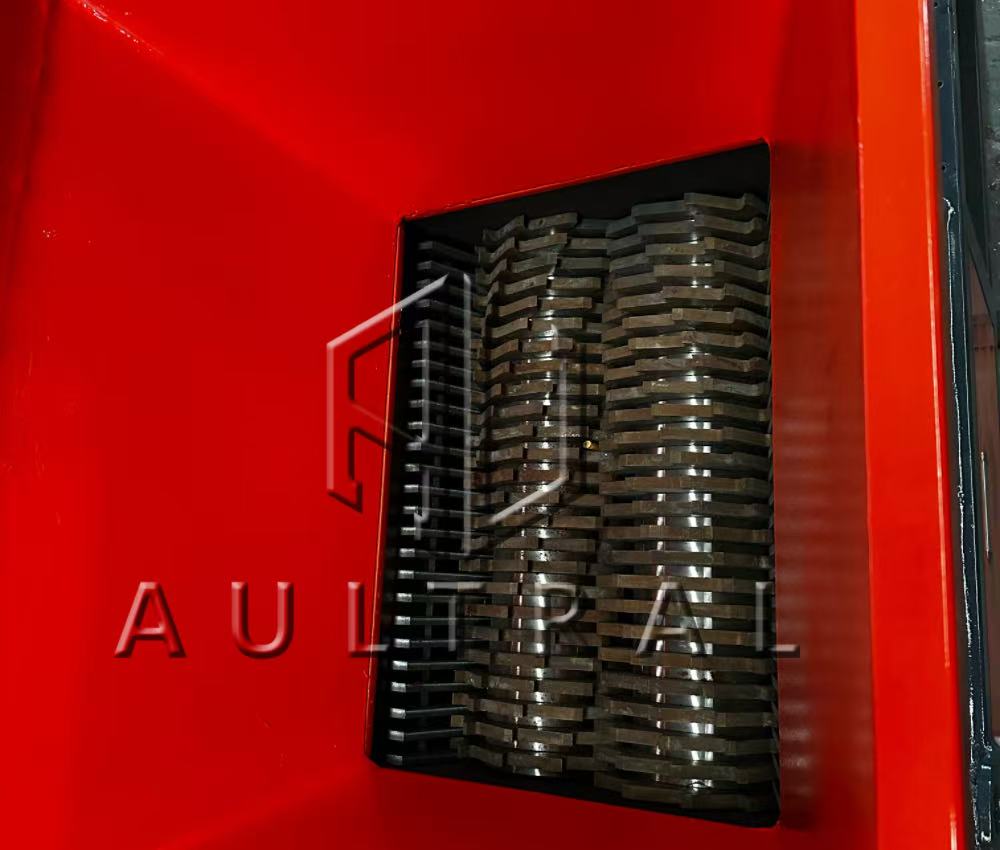

The structure of a small shredder usually includes a motor, one or two rotating shafts, and sharp blades that cut or tear materials. Depending on the design, some machines also include a screen that controls the final particle size. This allows users to adjust the shredder’s output to meet specific needs.

Small shredders are not only practical but also versatile. They can process plastics, paper, wood scraps, light metals, crop residues, textiles, and even electronic waste. With their compact design, energy efficiency, and affordability, they play a key role in modern waste management and recycling systems.

Why Choose A Small Shredder

Space Saving Design

Small shredders take up less floor space compared to larger models. This is especially important for businesses with limited facilities, such as small recycling workshops, start-up factories, or offices. A compact shredder can fit easily without the need for major infrastructure changes. For small businesses and individual users, a large industrial shredder is often too expensive. Small shredders provide a lower purchase price, reduced maintenance costs, and simpler operation. Over time, they save money while still delivering consistent results.

Versatility Across Materials

One of the biggest advantages of small shredders is their ability to process many types of waste. From plastic bottles and packaging materials to paper, textiles, and light wood, these machines can handle diverse materials without needing multiple specialized devices. Some models can even shred small electronic waste like hard drives or circuit boards.

Energy Efficiency

Small shredders are designed with energy efficiency in mind. Their motors are smaller, and their blade systems are optimized to cut through material with minimal power consumption. This reduces electricity bills and supports sustainability goals for environmentally conscious businesses.

Easy Operation And Safety

Most small shredders feature simple control panels that allow quick start-up and operation. Safety switches, overload protection, and emergency stop buttons are standard in many models, ensuring that even less experienced operators can use the machine without risk.

How To Use A Small Shredder

Preparation Before Operation

Before using the machine, it should be placed on a stable surface and properly connected to the power supply. Safety covers must be checked, and the blades should be free from foreign objects that could cause damage or accidents.

Feeding Materials

Materials should be fed gradually into the shredder. Overloading the machine may lead to blockages or strain the motor. Large pieces of waste should be pre-cut or broken down before being placed in the feed opening.

Monitoring Operation

During use, operators should watch for irregular noises, vibrations, or slowdowns in processing. These may signal that the shredder is overloaded or that maintenance is required. Continuous monitoring ensures smooth operation and protects the machine from damage.

Regular Maintenance

Like any mechanical equipment, small shredders require regular care. Blades should be cleaned, sharpened, or replaced when worn. Lubrication of moving parts keeps the machine running smoothly. If the shredder has a cooling system, it must also be cleaned to avoid overheating.

Safety Guidelines

Operators should wear gloves and protective glasses. Hands should never be placed near the feed opening, and the emergency stop button must remain within reach. Following these guidelines ensures both user safety and machine longevity.

Applications Of Small Shredders

Recycling Industry

In recycling plants, small shredders help reduce plastic bottles, packaging materials, and cardboard into smaller particles that can be washed, melted, or reprocessed into new products. This is the first step in turning waste into valuable raw materials.

Manufacturing Workshops

Small factories often produce defective parts, wood scraps, or leftover textiles. A small shredder allows manufacturers to manage these wastes efficiently, keeping production areas clean and reducing disposal costs.

Agriculture And Farming

Farmers use small shredders to handle crop residues, straw, corn stalks, or other by-products. These materials can then be used for composting, animal bedding, or as raw material for biomass energy. Shredding reduces bulk, making transportation and storage much easier.

Office And Household Use

In office environments, shredders are essential for destroying confidential documents and reducing paper waste. In households, they are useful for managing packaging waste, small pieces of wood, or old clothing that would otherwise take up space.

E-Waste Recycling

As electronic waste continues to grow worldwide, small shredders provide an environmentally friendly way to destroy and recycle items such as circuit boards, wires, or hard drives. This helps prevent data theft while also supporting e-waste recycling efforts.

How To Choose The Right Small Shredder

Consider The Material Type

The first step in selecting a shredder is identifying the main material to be processed. For plastics, a model with strong rotating blades may be ideal. For wood or crop residues, a shredder with durable shafts and a higher torque motor is recommended.

Evaluate Capacity And Output Size

Shredders vary in throughput capacity, usually measured in kilograms or tons per hour. Businesses should choose a model that matches their daily or monthly waste volume. Screens can also be selected based on the desired output size.

Check Energy Consumption

Since small shredders are often used in limited facilities, energy efficiency matters. Choosing a model with a reliable but low-power motor ensures lower electricity bills without sacrificing performance.

Look At Safety Features

Safety should never be compromised. A good small shredder should include overload protection, emergency stops, and secure covers to prevent accidents during operation.

After-Sales Service And Spare Parts

Since blades and components eventually wear out, it is important to choose a supplier that provides quick access to spare parts and technical support. This ensures minimal downtime and long-term machine value.

Conclusion

A small shredder is more than just a piece of equipment—it is an essential tool for businesses, farmers, offices, and households looking for efficient waste management. With compact size, affordable cost, and versatility across materials, small shredders bring both economic and environmental benefits.

They reduce the volume of waste, make recycling easier, and help transform discarded materials into valuable resources. Their energy efficiency and ease of use make them a practical solution even for beginners or small facilities with limited budgets.

In today’s world, where sustainability matters more than ever, choosing a small shredder is a smart and forward-looking decision. Whether it is for recycling plastics, managing agricultural residues, destroying confidential documents, or processing e-waste, these machines provide reliable performance and long-term value.

By adopting small shredders, individuals and businesses contribute to cleaner environments, reduced landfill waste, and a circular economy where materials are reused instead of discarded. A small shredder may be compact in size, but its impact on sustainability and efficiency is undeniably large.