In today’s world, managing waste effectively is not just an environmental concern—it’s a critical part of business operations across industries. Whether you are dealing with cardboard, plastics, textile waste, or scrap metals, a baler machine can transform your waste-handling process into a streamlined, cost-effective operation. In this comprehensive guide, we’ll walk you through everything you need to know about baler machines, from how they work to choosing the right one for your needs.

📦 What Is a Baler Machine?

A baler machine is a piece of industrial equipment designed to compress and bind materials into compact, easy-to-handle bales. The primary purpose of a baler is to reduce the volume of recyclable or waste materials, making them easier to transport, store, and process.

Baler machines are widely used in industries such as:

-

Recycling and waste management

-

Manufacturing and packaging

-

Retail and logistics

-

Agriculture (for straw, hay, etc.)

-

Printing and paper production

🔧 How Does a Baler Machine Work?

The basic working principle of a baler is simple:

-

Loading – Material is loaded into the compression chamber manually or via conveyor.

-

Compression – A hydraulic or mechanical press applies force to compress the material.

-

Tying – The compressed material is bound using wire, plastic, or strapping.

-

Ejection – The finished bale is pushed out of the machine, ready for storage or transport.

Depending on the machine type, some balers are semi-automatic or fully automatic, reducing the need for manual handling and improving productivity.

🧰 Types of Baler Machines

There are several types of baler machines, each suited for specific materials and operational requirements.

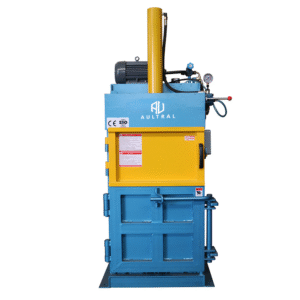

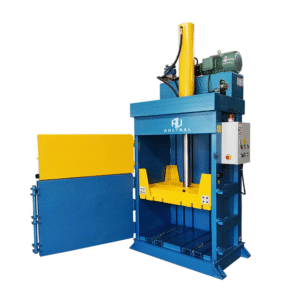

1. Vertical Baler

-

Ideal for: Small to medium volumes of cardboard, plastic film, textile waste.

-

Features: Compact design, manually operated, space-saving.

-

Advantages: Lower cost, easy to install and use.

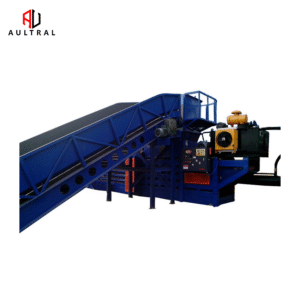

2. Horizontal Baler

-

Ideal for: Large volumes of recyclables, especially in industrial settings.

-

Features: Higher throughput, conveyor-fed, can be semi or fully automatic.

-

Advantages: Efficient, time-saving, suitable for continuous operations.

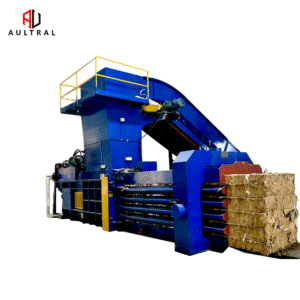

3. Fully Automatic Baler

-

Ideal for: High-capacity operations like recycling centers and factories.

-

Features: Fully automated loading, compressing, tying, and ejecting.

-

Advantages: High efficiency, minimal labor, consistent bale quality.

4. Manual-Tie Baler

-

Ideal for: Facilities that require manual control over bale tying.

-

Features: Semi-automatic, manual wire strapping.

-

Advantages: Cost-effective for moderate volume users.

5. Specialty Balers

-

For materials like:

-

Scrap metal (metal baler)

-

Foam and textiles

-

Agricultural waste (hay balers)

-

🏭 Common Materials Baled

Baler machines are highly versatile and can be used for a wide range of materials:

-

🟩 Cardboard & OCC (Old Corrugated Containers)

-

🟦 Plastic bottles (PET), film, and containers

-

🟥 Scrap metals (aluminum, steel)

-

🟨 Textile waste and rags

-

🟫 Paper and newspaper

-

🌾 Agricultural materials like straw, hay, and cotton stalks

Each material requires a different level of compression and bale tying method, which influences the type of baler you need.

✅ Benefits of Using a Baler Machine

Investing in a baler machine comes with a wide range of advantages:

1. Space Saving

Baled waste occupies significantly less space than loose material, helping you keep your workspace organized.

2. Cost Efficiency

Reducing waste volume decreases transportation and storage costs. You might even earn money by selling baled recyclables.

3. Compliance

Helps meet environmental regulations and improve your company’s sustainability image.

4. Improved Safety

Keeps waste in one place, minimizing fire hazards and tripping risks.

5. Time-Saving

Automatic and semi-automatic models streamline the process, saving hours of manual work.

🧠 How to Choose the Right Baler Machine?

Selecting the right baler depends on several key factors:

-

Material Type – Different materials have different compression needs.

-

Bale Size Requirements – Consider storage and transport convenience.

-

Volume of Waste – Choose vertical balers for small volumes, horizontal or automatic for large volumes.

-

Space Availability – Vertical balers save space; horizontal machines need more room.

-

Budget – Manual and vertical balers are cheaper upfront; automatic ones offer long-term savings.

-

Operation Mode – Do you prefer manual control or full automation?

💡 Tip: If you’re unsure, consult with a professional supplier. A trustworthy manufacturer can offer customized baler solutions based on your needs.

🛠️ Maintenance & Safety Tips

-

🔧 Regularly check hydraulic systems and oil levels.

-

🧽 Clean the machine to prevent material buildup.

-

⚠️ Always train staff to operate the baler safely.

-

🧰 Replace worn-out parts promptly to avoid downtime.

Well-maintained machines last longer and ensure safer operation.

❓ Frequently Asked Questions

Q1: How long does a baler machine last?

A quality baler can last 8–15 years with proper maintenance.

Q2: What is the difference between a vertical and a horizontal baler?

Vertical balers are more compact and suitable for lower volumes, while horizontal balers are designed for continuous, high-capacity use.

Q3: Can one baler handle different materials?

Some balers are multipurpose, but it’s best to match the machine type with the primary material for efficiency.

📞 Ready to Upgrade Your Waste Management?

A baler machine is more than just equipment—it’s a smart investment for improving efficiency, reducing waste, and contributing to a cleaner planet. Whether you’re a small retailer or a large-scale recycling facility, there’s a perfect baler solution waiting for you.

👉 Looking for expert advice or a customized quote? Contact us today! Our team specializes in baler and shredder manufacturing and can guide you to the ideal machine for your business.

Keywords for SEO: baler machine, vertical baler, horizontal baler, waste management equipment, recycling baler, cardboard compactor, industrial baler, automatic baler, baler for plastic, baler supplier